Types Of Pumps: Find The Right Pump For The Job

This is a complete guide to finding the right pump for your specific application.

In this guide, you’ll learn everything there is to know about the different types of pumps available, enabling you to:

- Identity the right pump for your application

- Save time and money when buying a pump

- Increase the life of your pump and plumbing system

So, if you’re in the market for a pump, but you’re not sure which one is right for your application, then this is the guide for you.

Let’s get started.

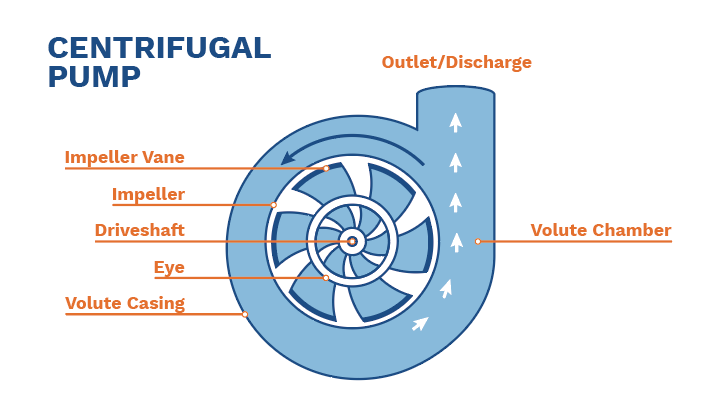

Centrifugal Pump

A centrifugal pump is a general name used to describe any pump that operates using one or more impellers. Think ‘aeroplane engines’ and you are on the right track.

Best choice for: Low viscosity liquids like water. Operate at their best in high passing rate systems.

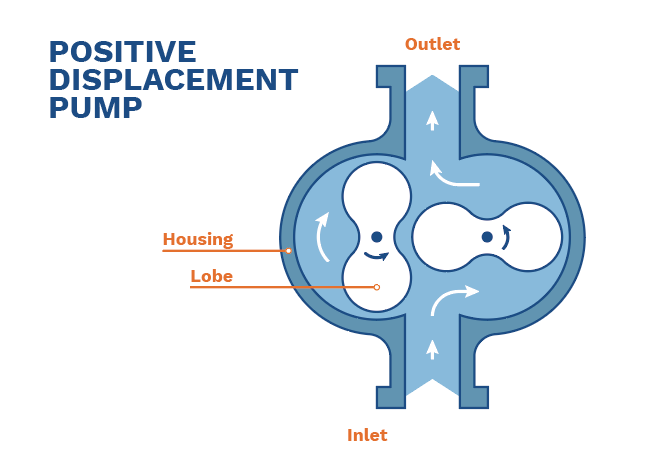

Positive Displacement Pump

A positive displacement pump does not have impellers. Instead, they use rotating, reciprocating or pulsing parts to pump liquid.

Best choice for: High viscosity liquids. Operate best when moving liquids safely at a low speed.

For more information on the differences between Positive Displacement Pumps and Centrifugal Pumps, please read our complete guide here.

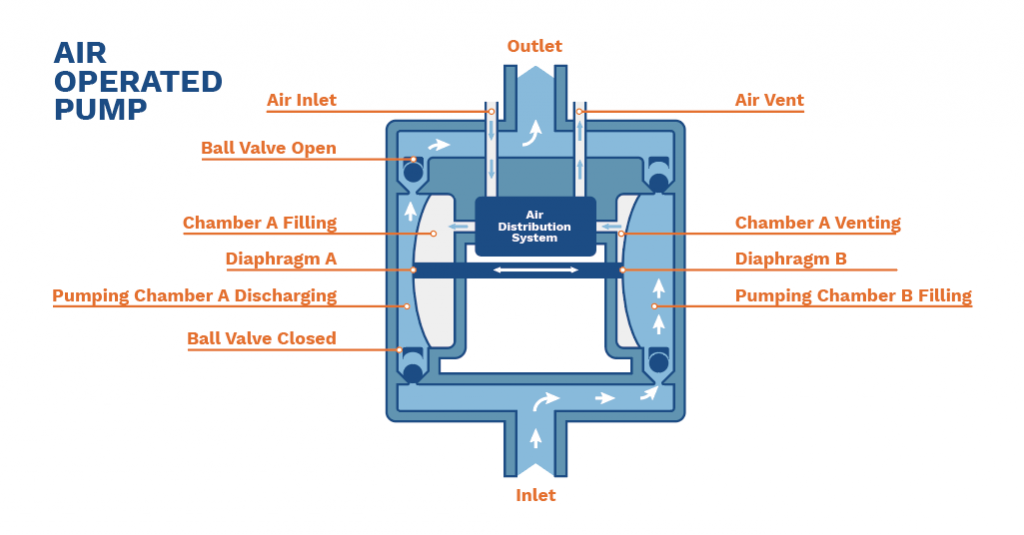

Air Operated Diaphragm Pump

Air operated diaphragm pumps are used in a variety of different industries, pumping a wide range of liquids including oil, petrol, food, beverage items, and even cement.

The air operated diaphragm pump is a type of positive displacement pump that uses compressed air to move two diaphragms instead of an electric motor.

The pump works by shifting compressed air from one chamber to another, moving the diaphragms of the pump and forcing liquid from the intake of the pump to the discharge point.

Best Choice for: Pumping liquids that contain a large number of solids in industries where electricity isn’t readily available. Also a good choice for pumping liquids of a corrosive nature.

Booster Pump

Booster pumps are generally used in domestic settings where a further boost of pressure is needed in a system. Booster pumps are usually operated with a centrifugal design, using the impellers to boost the pressure of the liquid as it passes through the pump.

Booster Pumps come in various designs depending on the brand or model and they can work with a single impeller or multiple impellers.

Best Choice for: Improving water pressure in domestic settings (drinking water, toilets, taps). Generally, only work when pumping potable water

For more information about Booster Pumps please read our dedicated complete guide here.

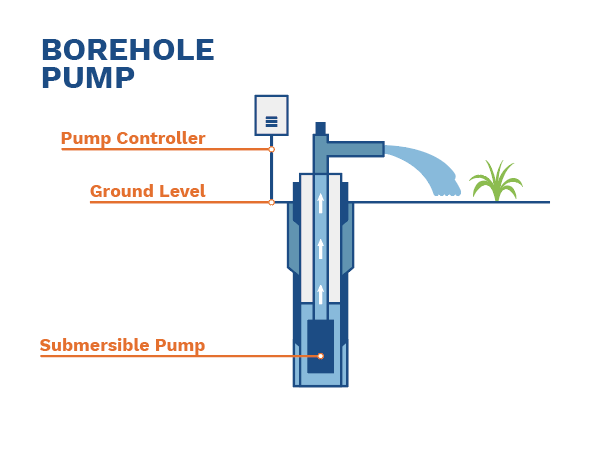

Borehole/Well Pump

Borehole/Well pumps are a type of vertical turbine pump that are used to pump water from underground water sources.

The pump works by driving an impeller that draws water into the pump. Once the water is inside the tube the water is pumped through the body of the tube and brought to the surface.

All well-pumps will come hermetically sealed to prevent water from entering the motor and causing a short circuit.

Best Choice for: Situations where access to a water supply is difficult. They can be used as part of irrigation systems, fire pumps and general potable water distribution.

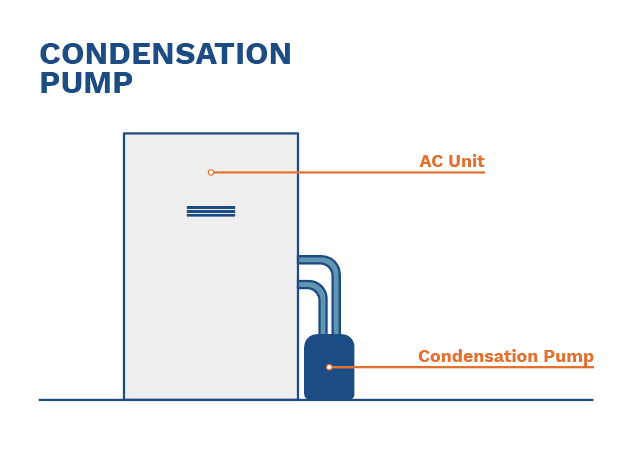

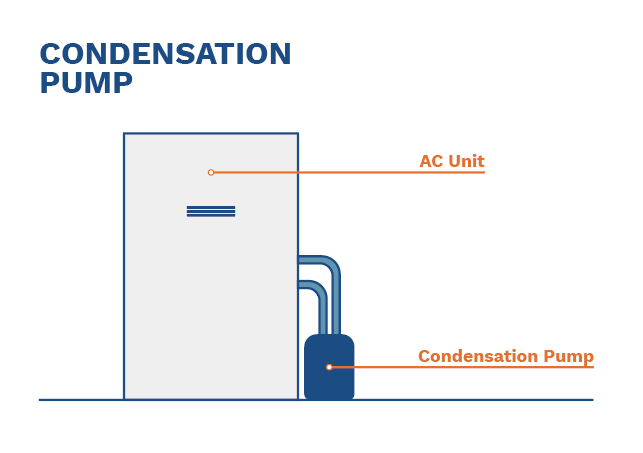

Condensation Pump

A condensate pump is a specific type of pump that collects condensation in a heating or cooling system.

A condensation pump works by having a reservoir where condensation is collected. Once a certain amount of condensation has been collected the pump will be switched on via a float switch. The pump will then continue to run and pump out the water until the float returns to the lower level.

Best Choice for: Condensation pumps will usually come fitted inside of heating or air conditioning systems. In the event that you need to replace a condensation pump, great care should be taken in handling the pump. Impurities will be collected in the filter and the chemicals found inside of a condensation pump can be harmful to your health.

Macerating Pump (sanitary)

When the flush is activated in normal toilets the waste is sent into the main drain or sewer line using a gravity system. In the event that a toilet is located below or away from the main sewer line, a macerator pump will be needed to “upflush” the waste from the toilet to the sewer line.

The Macerating pump is a type of pump used for sewage is usually operated with a centrifugal design, using the impellers to boost the pressure of the liquid after a float switch is activated.

Best Choice for: Macerating pumps are generally only used in a bathroom system that is below or away from the main sewer line. Systems that can use a macerating pump include the toilet, shower, sink and bath.

If you would like further information about macerating (saniflo) pumps please read our guide here

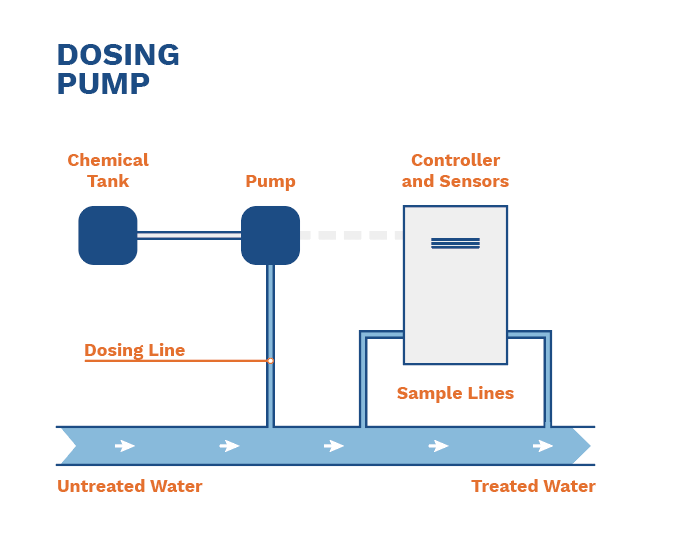

Dosing Pump

A dosing pump is required on the occasions where it is necessary to add chemical treatments to a water supply.

This type of pump accurately measures the amount of water passing through the pump and adds (dose) the required percentage of chemical into the system. This allows you to be safe in the knowledge that you have the correct chemical to water solution.

Best Choice for: A dosing pump can be used in conjunction with a variety of water supplies. These include swimming pools, aquariums and hot tubs. They can also be used in certain ponds but this depends on the pond manufacturer.

Drum Pump

Drum pumps work by having a narrow vertical shaft that fits inside the drum opening. When the motor is attached to the top of the vertical shaft the motor kickstarts an impeller, which pumps the liquid out of the barrel.

Best Choice for: Emptying barrels, tanks, IBCs and drums. Frequently found in factories, the pumps are used to remove liquid from the 100 or 200-litre barrels that make large liquid transportation simple.

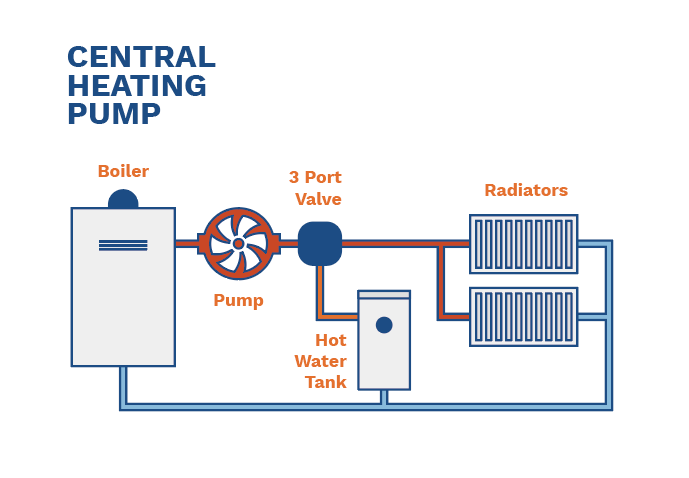

Central Heating Pump

A central heating pump is a vital part of your central heating system. When the central heating system heats up the water in the boiler it needs to move quickly around the home to heat radiators. If the water is slow to move around your home you can often struggle to sufficiently heat certain areas of the home. The central heating pump adds an extra element of pressure to the system, speeding up the process.

Best Choice for: Central heating pumps only have one appliance use - central heating systems. Most central heating pumps will come pre-fitted in your central heating system.

For more information on pumps for heating systems please read our dedicated complete guide to buying a central heating pump here.

Rainwater Harvesting Pump

Rainwater harvesting pumps are hermetically sealed systems that utilise a float switch to deliver water around your home. The major difference between a submersible pump and a rainwater harvesting pump is that the latter has the ability to filter the water before pumping it around your home. This allows you to rest assured that you are drinking, washing or cleaning with safe water.

Best Choice for: As the name suggests, rainwater harvesting pumps are utilised in rainwater harvesting systems. They can also be used as an alternative to submersible pumps in irrigation or water supply systems, but please keep in mind that they work at a considerably lower pressure.

If you would like further information about rainwater harvesting pumps please read our complete guide here.

Shower Pump

There are two types of pumps to consider when boosting the pressure in a shower.

Firstly, you have a positive head shower pump. This pump is a gravity-operated system which is started when you are getting a minimum flow rate of 0.6 litres per minute.

The second pump to consider is the universal head shower pump. This pump is installed when the showerhead level is level, or above the cold water storage tank.

These pumps are often used in loft conversions, residential flats and home renovations.

Best Choice for: The main use of a shower pump is when you are experiencing pressure issues with the shower. If your Monday morning does not start with an invigorating and rejuvenating shower, then it is time to invest in a shower pump.

For more information on shower pumps please take a look at our complete guide here.

Submersible Pump

As the name suggests, submersible pumps are designed to be submerged in bodies of water. Usually used in areas of flooding or well systems, this pump is hermetically sealed to ensure the inner electrics are protected, a submersible pump is either air or oil fuelled and can accommodate a range of impellers to tackle liquids and solids of different size and viscosity.

Best Choice for: Useful in a variety of situations where you may want to remove unwanted bodies of water, you will find submersible pumps in irrigation systems, well systems and they can also be operated in the event of flooding.

If you would like further information about submersible pumps please read our complete guide here.

Solids Handling Pump

Solids handling pumps are a centrifugal design that can handle rocks, debris and other solids while clearing wastewater. Similar to submersible pumps in design, solids handling pumps use a large reinforced impeller to pump the type of solids found when clearing wastewater. Although they are similar to submersible pumps in design and theoretical application, solids handlings should not be submerged underwater.

Best Choice for: Pumping wastewater which contains debris, rocks and other solids that may damage a submersible pump. Often found on construction sites, mines and pits where the risk of dirty water containing debris is high. They can also be used in the event of flooding but should be kept out of water at all times.